Here, only according to JS/T 8854.2-2001 standard, the selection of G II CL series and its derived types of drum coupling is explained. For the choice of other types of products, please consult our technical department when necessary.

Generally speaking, the selection of drum gear coupling should be checked in the following three aspects:

1. Intensity check

The strength of the coupling shall meet: Tc≤Tn...... (1)

Type (1) :

Tc 1 Calculation torque, N. M;

Tn 1 nominal torque, N.m (as shown in Table 1);

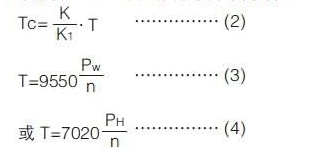

1.1 Calculation of torque Tc I is obtained from equations (2), (3) and (4)

In Equation (2), (3) and (4) :

T one theoretical torque, N● M;

Pw - Driving power, KW;

PH 1 driving power, HP;

N 1 working speed, r/min;

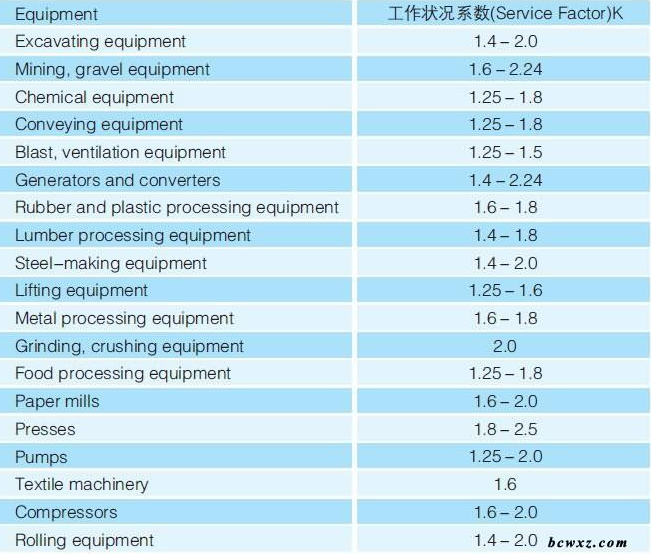

K - Working condition coefficient; (see table 1)

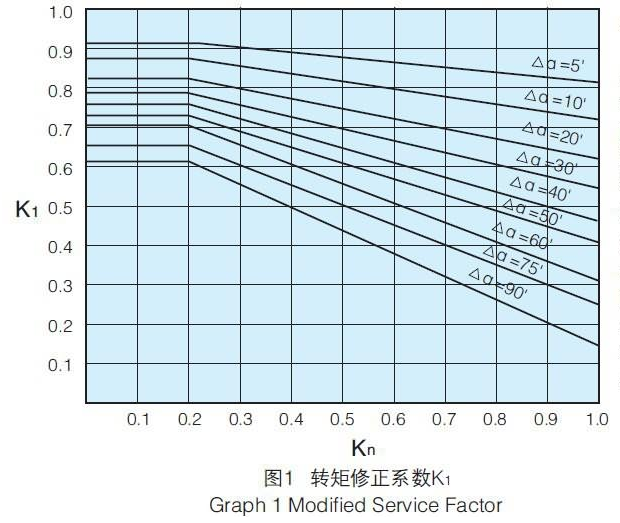

K1-torque correction factor; (see figure 1)

1.1.1 Modified service factor K1 (Refer to Graph 1)

1.1.2 Service factor K is determined by the load sustained by the coupling in actual application (Refer to Table 1)

2. The working speed n of the coupling must also meet the following requirements:

n ≤[n]

n ≤0.75nk

Or n ≥1.35 nk

Type: nk-coupling first-order critical speed, R /min;

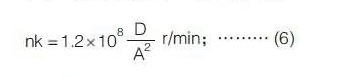

2.1 Calculation method of NK

2.1.1 For coupling with intermediate shaft, nk is calculated according to Formula (6) :

D- Intermediate shaft diameter, mm;

A- The distance between the middle points of the tooth width of both ends of the outer teeth of the shaft sleeve, mm;

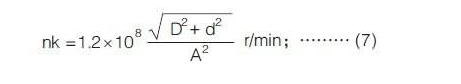

2.1.1 For couplings with intermediate nozzles, nk is calculated according to Formula (7) :

D- Outer diameter of the intermediate pipe, mm;

D - The inner diameter of the intermediate pipe, mm;